Modern Methods of Construction

The housing crisis post World War 1 spurred the need for non-traditional methods of house construction. Since then although in various forms, non-traditional means of construction have been instrumental in satiating the immediate need of building homes in less time. Today, it would be fair to say that the Modern Methods of Construction (MMC) have certainly taken a leaf out of the old book.

Driven by the need for rapid housing in the 20th century, new techniques evolved to improve the efficiency of construction. Precast concrete was available for construction through mass production across the UK in the 1920’s. This adoption resulted in significant reduction in the time taken to construct homes thus marking precast/prefabricated concrete the first large-scale adoption of modern methods of construction (MMC). This was followed by steel frame construction and Industrialised Building Systems (IBS), the latter having marked the inception of pre-engineered components being manufactured in factories in the 1960s and then came the era of modular construction in the 1970s.

All these developments have today helped in improving the speed, quality, and efficiency of construction while also greatly reducing the impact on environment.

What are Modern Methods of Construction?

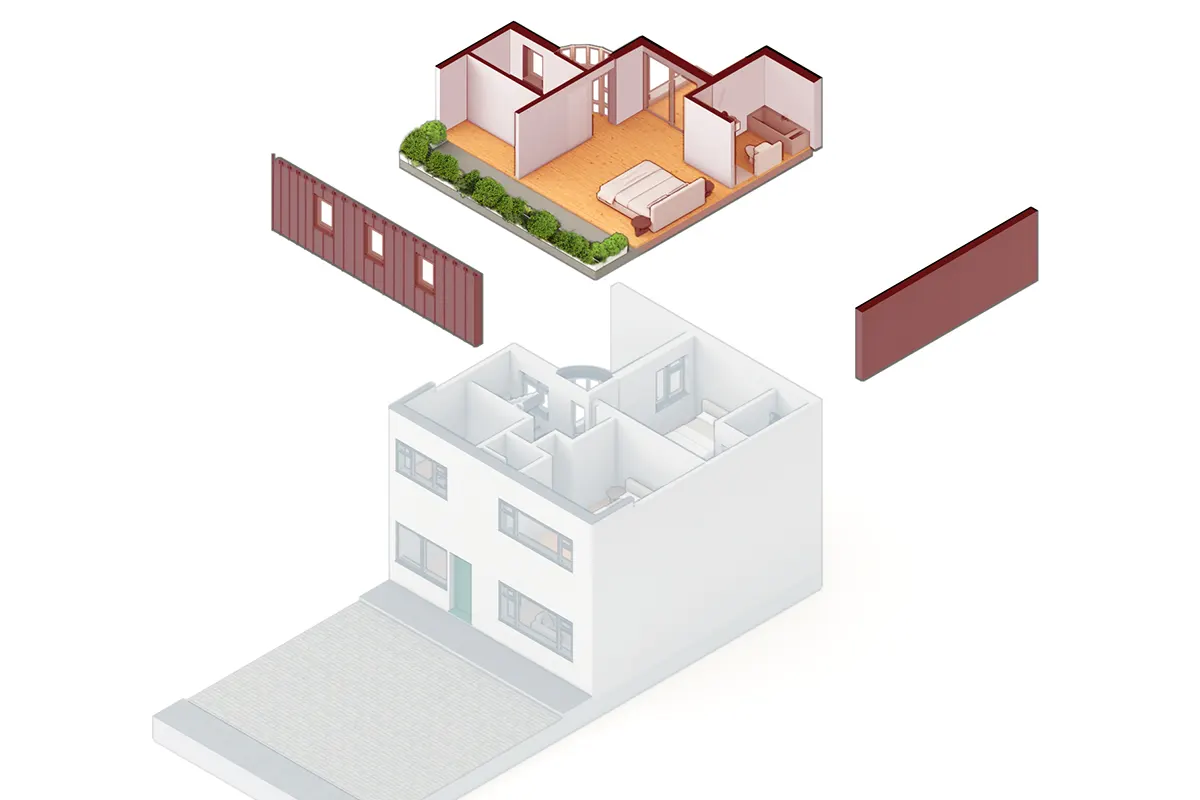

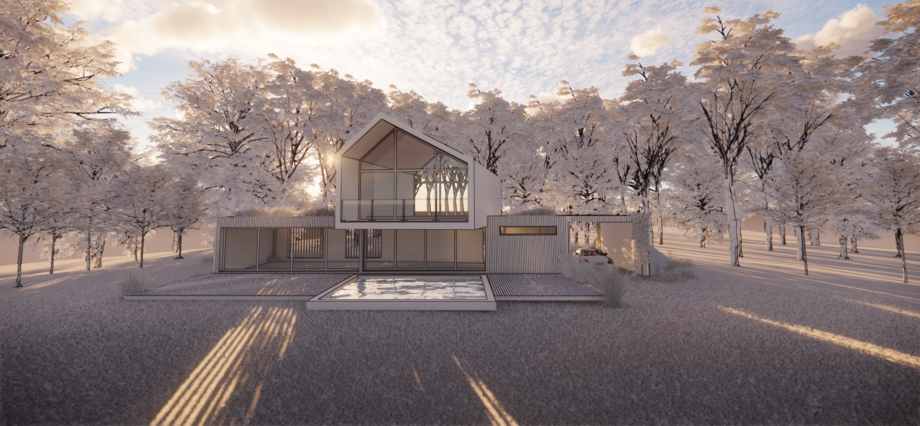

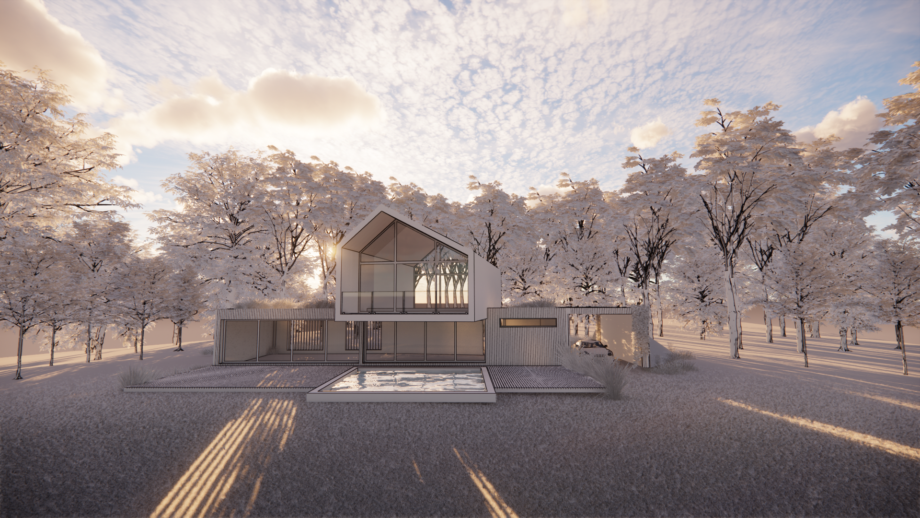

From factory-produced components and structures to modular constructions enabling quicker assembly of parts at onsite and advanced building techniques that have accelerated productivity and improved efficiency, modern methods of construction have come a long way.

Historical Impact of Non-traditional Practices

The year 1970 in the UK, saw a rapid surge where more than 550,000 dwellings attained realisation. This was the era where modular construction methods had made its way. So, overall, the revolution of non-traditional construction methods has indeed born fruits.

Innovative Practices of Modern Methods of Construction

According to data, adoption of modern methods of construction has accelerated the speed of construction by a significant 35%. The overall cost has seen a substantial 30% reduction.

Let’s take a look at a few MMC practices that revolutionised the construction industry –

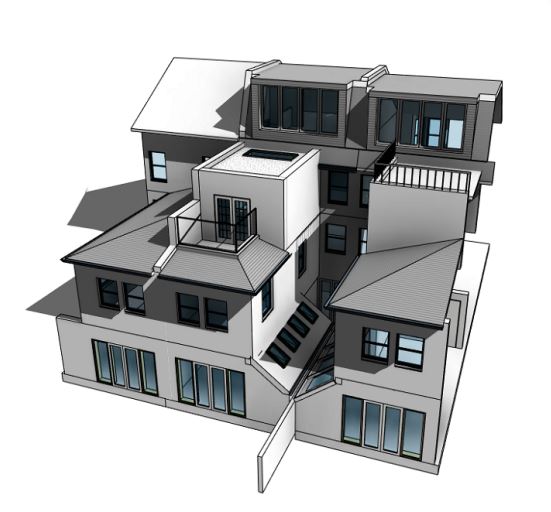

- 3D Volumetric Construction involves building three-dimensional units within a factory premises and then shipping onsite.

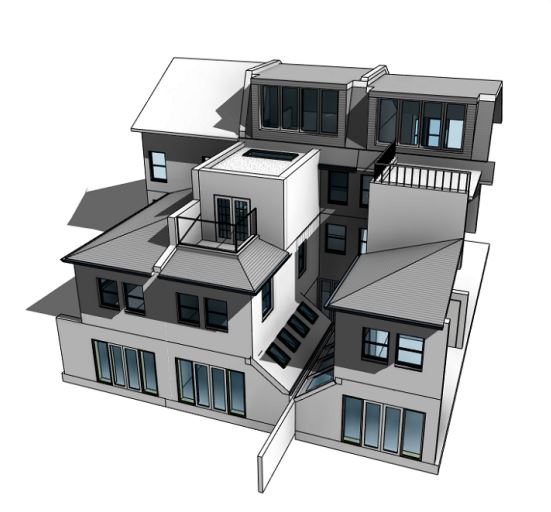

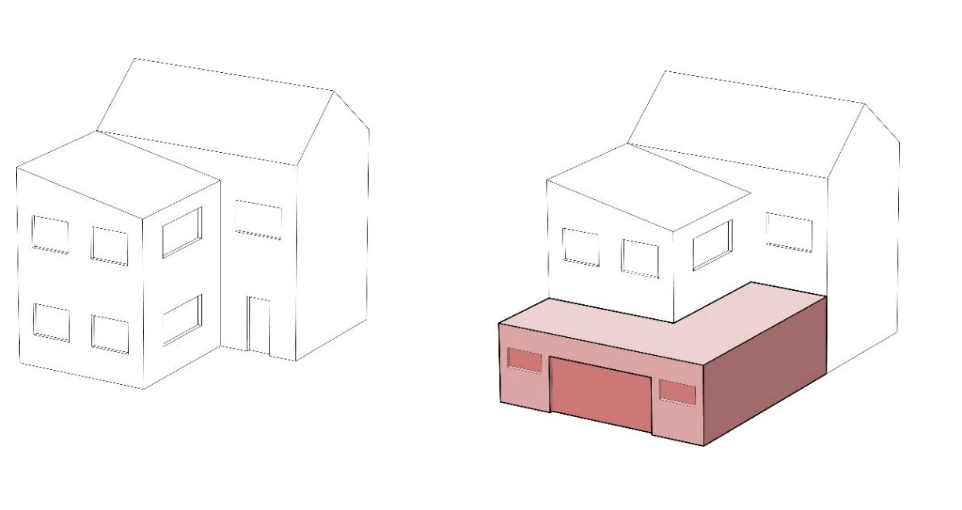

- Creating panels as units in factories such that they can be quickly assembled onsite. These can be of timber, steel, or concrete to be used for floors, walls, and ceilings.

- 3D Printing as a method that uses a digital model in 3D to create construction elements.

- Precast concrete for foundations.

- Use of digital technology should be widespread to attain improved precision.

- Construction to be done offsite to help reduce the impact on environment.

- Mortgage lenders, financial service providers, insurers should be abreast about the safety and quality of MMC built homes.

- Governments to take measures such as recruiting young people to be trained for MMC building techniques by driving skill-oriented programmes, apprenticeships, etc.

Impact of MMC in the Residential Sector

- Increased Construction speed is one of the most significant of all outcomes under MMC where factory-built parts are taking less build time and faster delivery thus addressing the housing demand.

- Use of prefabricated components are averting the dependency of a large labour workforce onsite, thus positively contributing towards the issue of labour unavailability/shortages.

- Quality control has taken a leap as components are manufactured in a controlled and monitored environment with less vulnerability to external adversities.

- MMC techniques are greatly reducing carbon footprint and contributing towards attain energy efficiency by reducing wastage. This is because MMC enables optimum resource use by leveraging smart techniques, using modern design software, simulation, all of which help anticipate and estimate in advance.

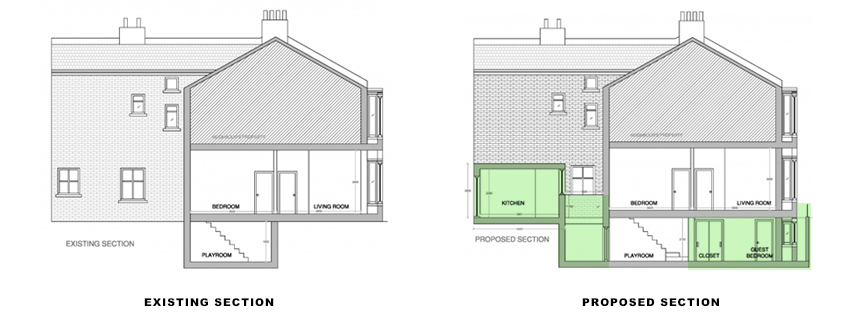

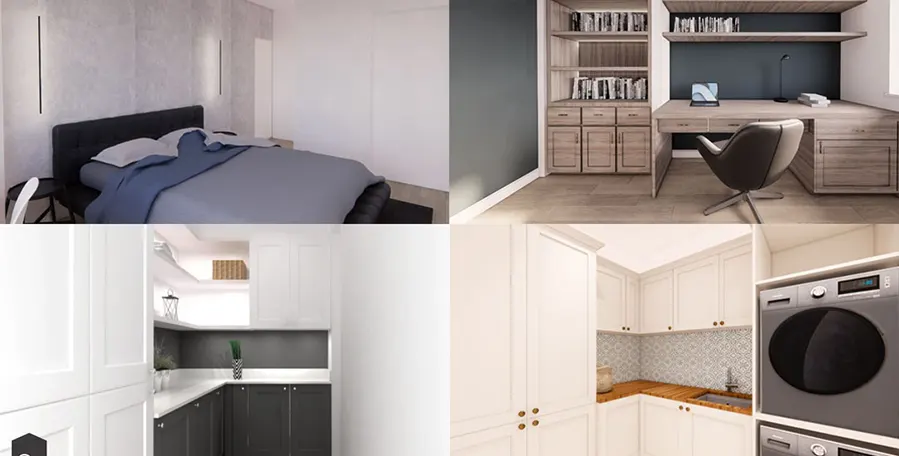

MMC Techniques in Residential Construction

- Volumetric construction that are manufactured off-site

Kitchen units, bathroom pods, utility units - Panelised systems or panel units

Open panels, SIPs, curtain walling, concrete panels. - Factory-built units

Prefabricated foundations, I-beams, attic joists (metal), prefabricated plumbing units, pre-assembled roof skeleton, roof & floor cassettes.

Examples of Houses Built Using MMC in the UK

- George Street, Croydon: A 44- and 38-story build-to-rent development in Croydon, south London. It’s the tallest modular residential scheme in the world.

- Excalibur Estate, Catford: A prefab estate in south London that was in use until recently.

- Mace’s jumping factory in Stratford: An example of MMC in London.

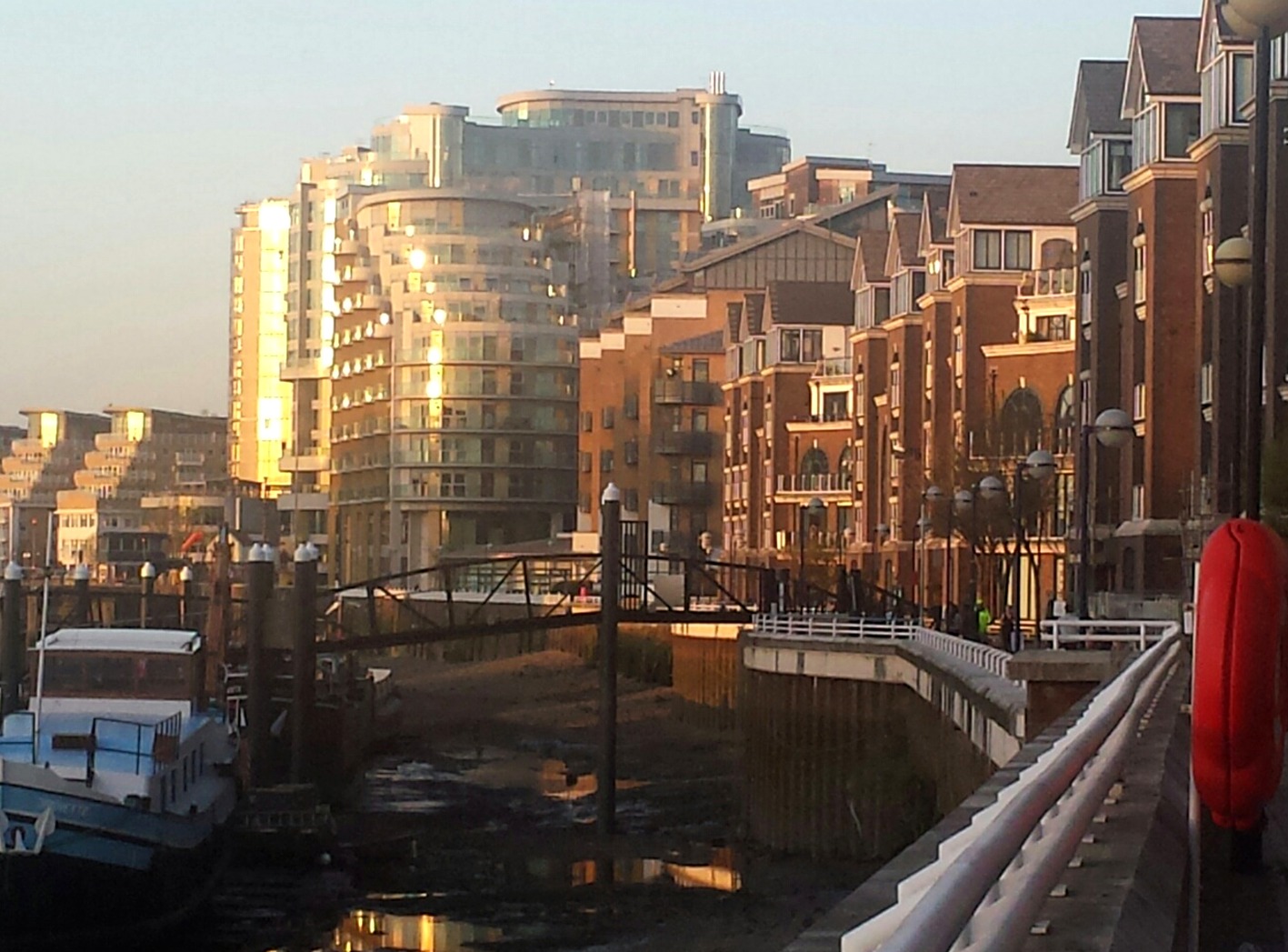

- Greenford Quay in London: An example of a residential building in the UK that uses MMC.

Conclusion

Though MMC techniques may not dominate traditional process at any immediate proximity, it is fair to say that they have come a long way and have established their impact in tiny yet important forms of construction as they continue their prowess in solving the biggest problem of the UK.

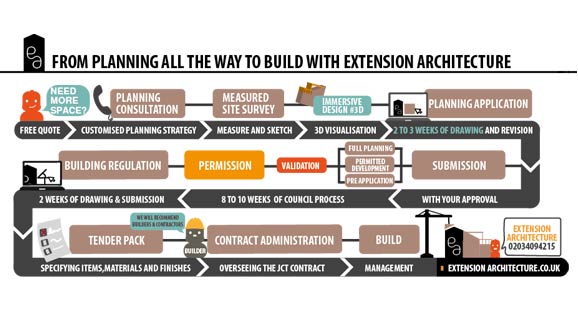

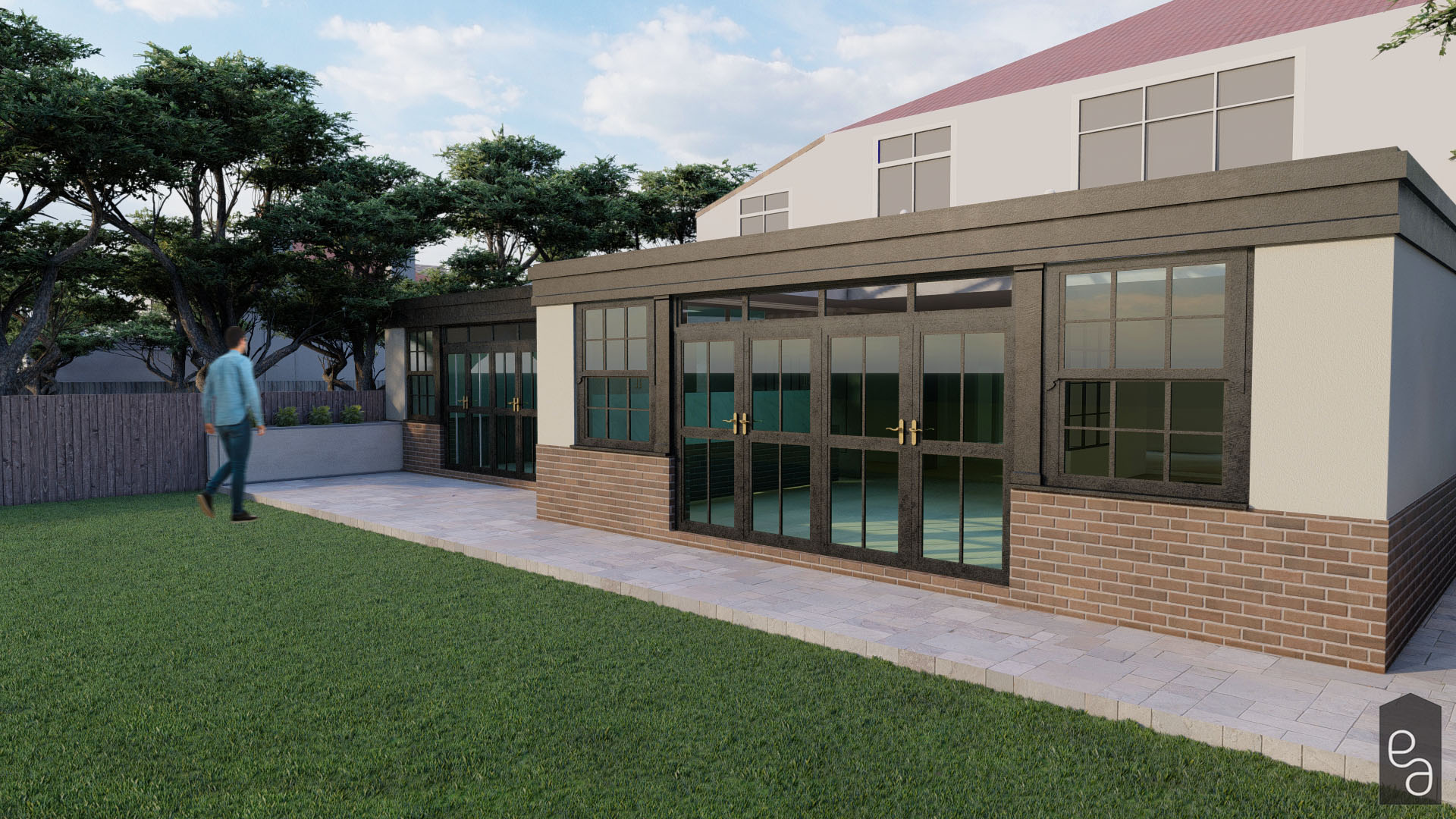

If you are planning to integrate MMC techniques into your new-build or an extension or a conversion project, contact our experts at Extension Architecture or visit us at our London location.